LOG 1023 INTRODUCTION TO MATERIALS MANAGEMENT WHAT IS CAPACITY MANAGEMENT

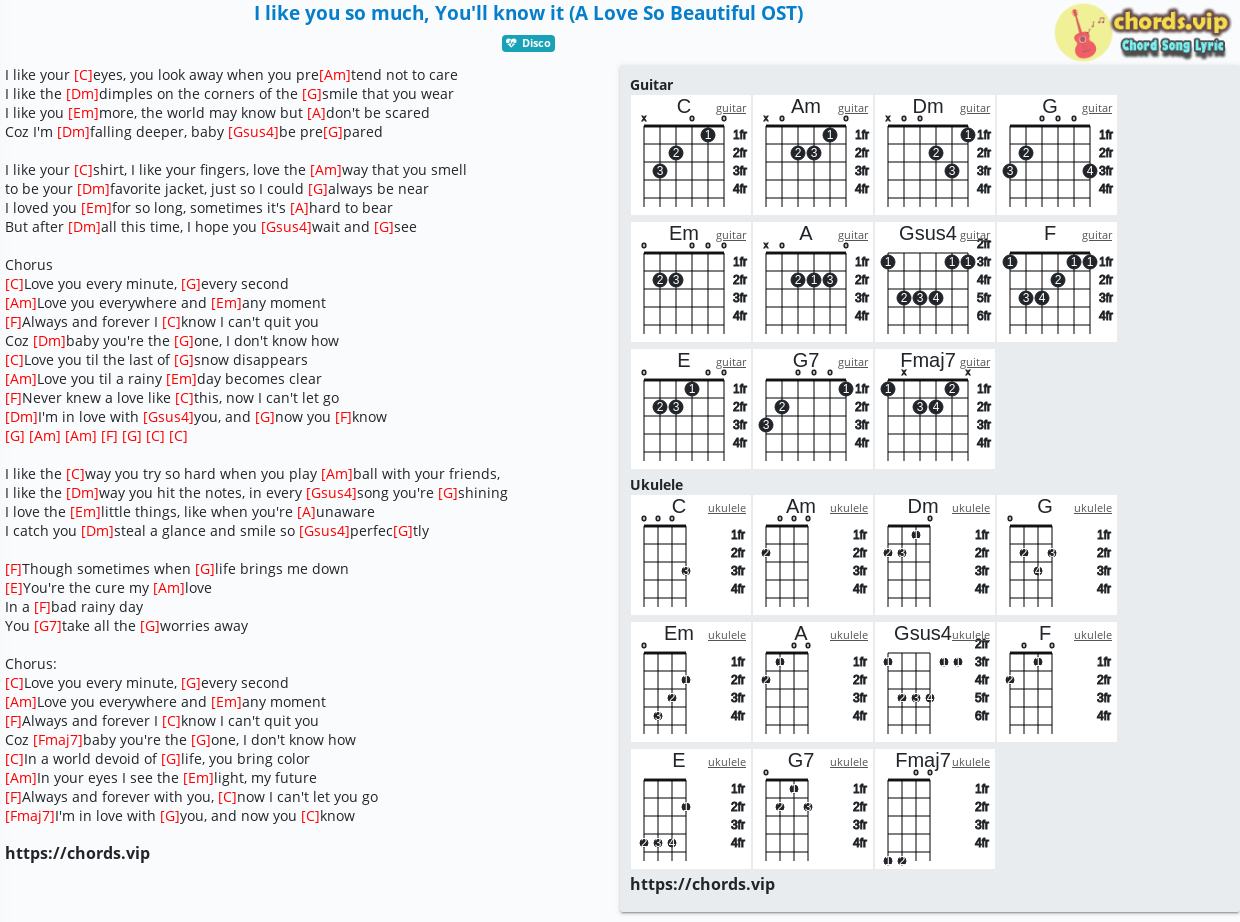

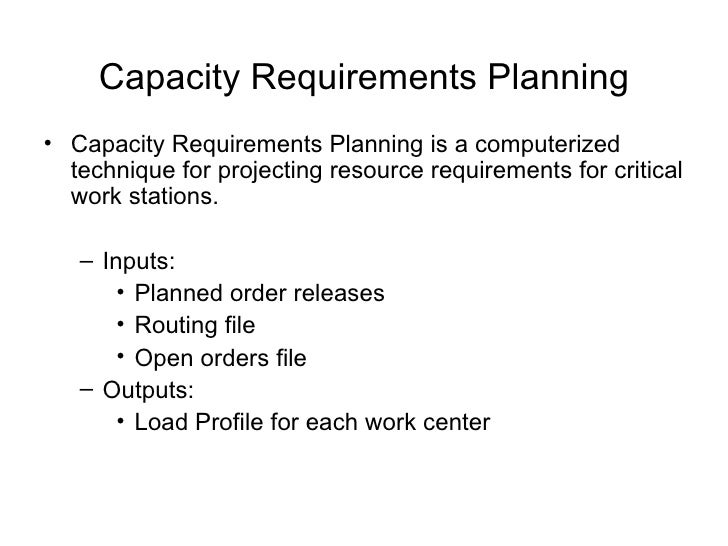

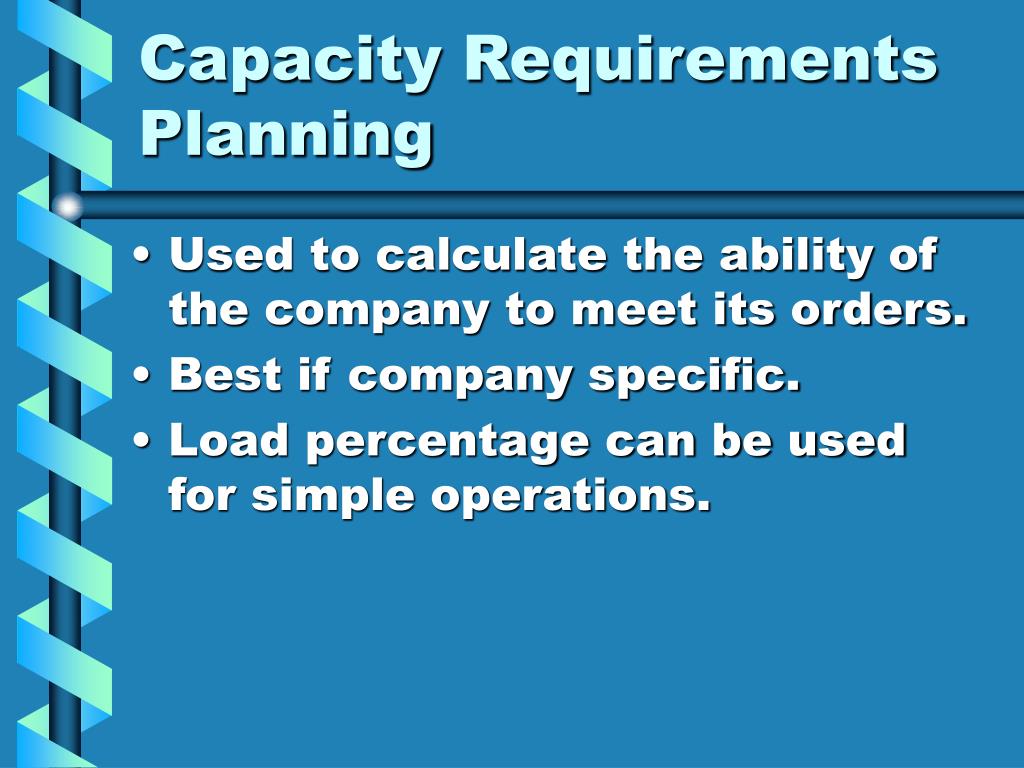

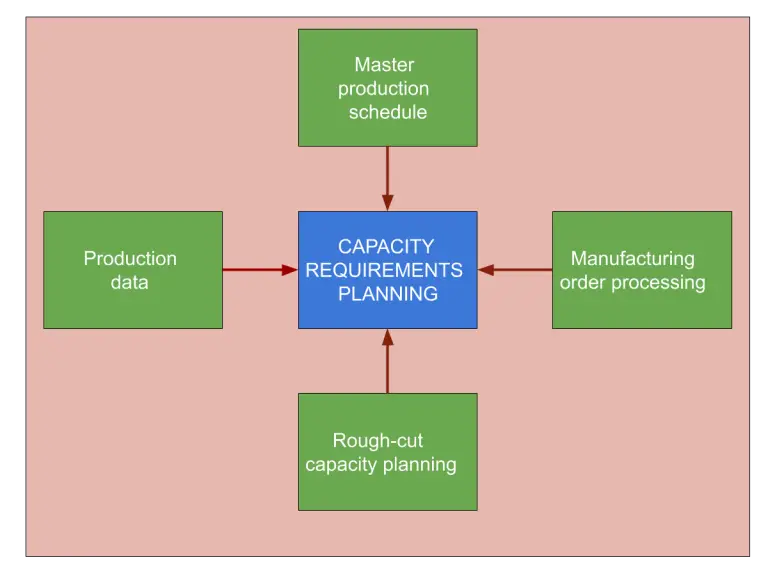

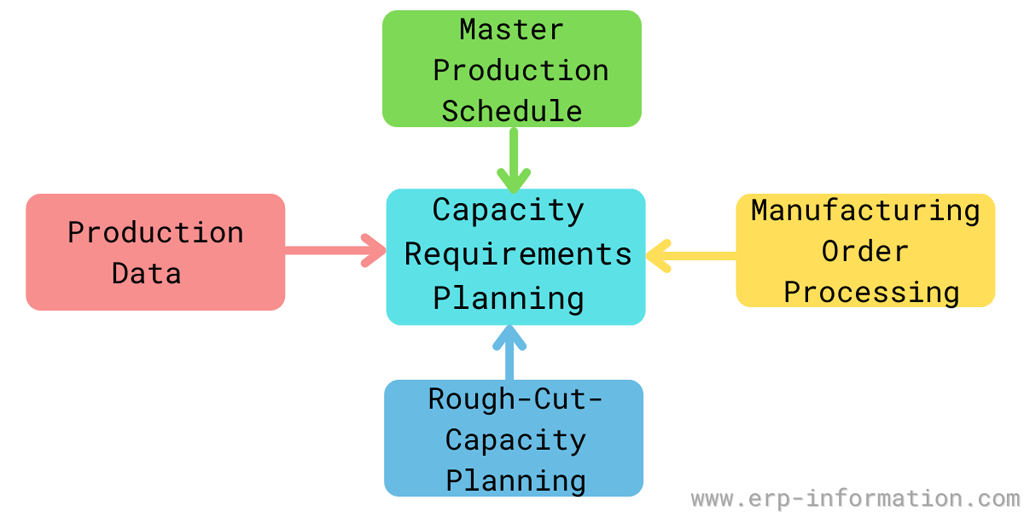

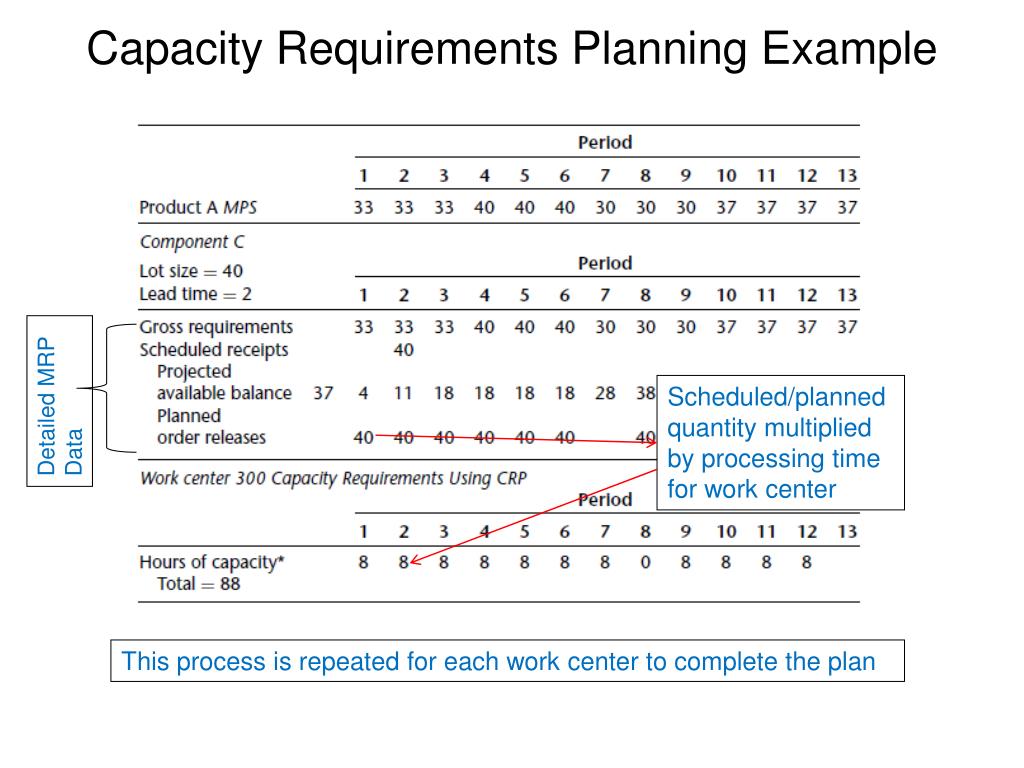

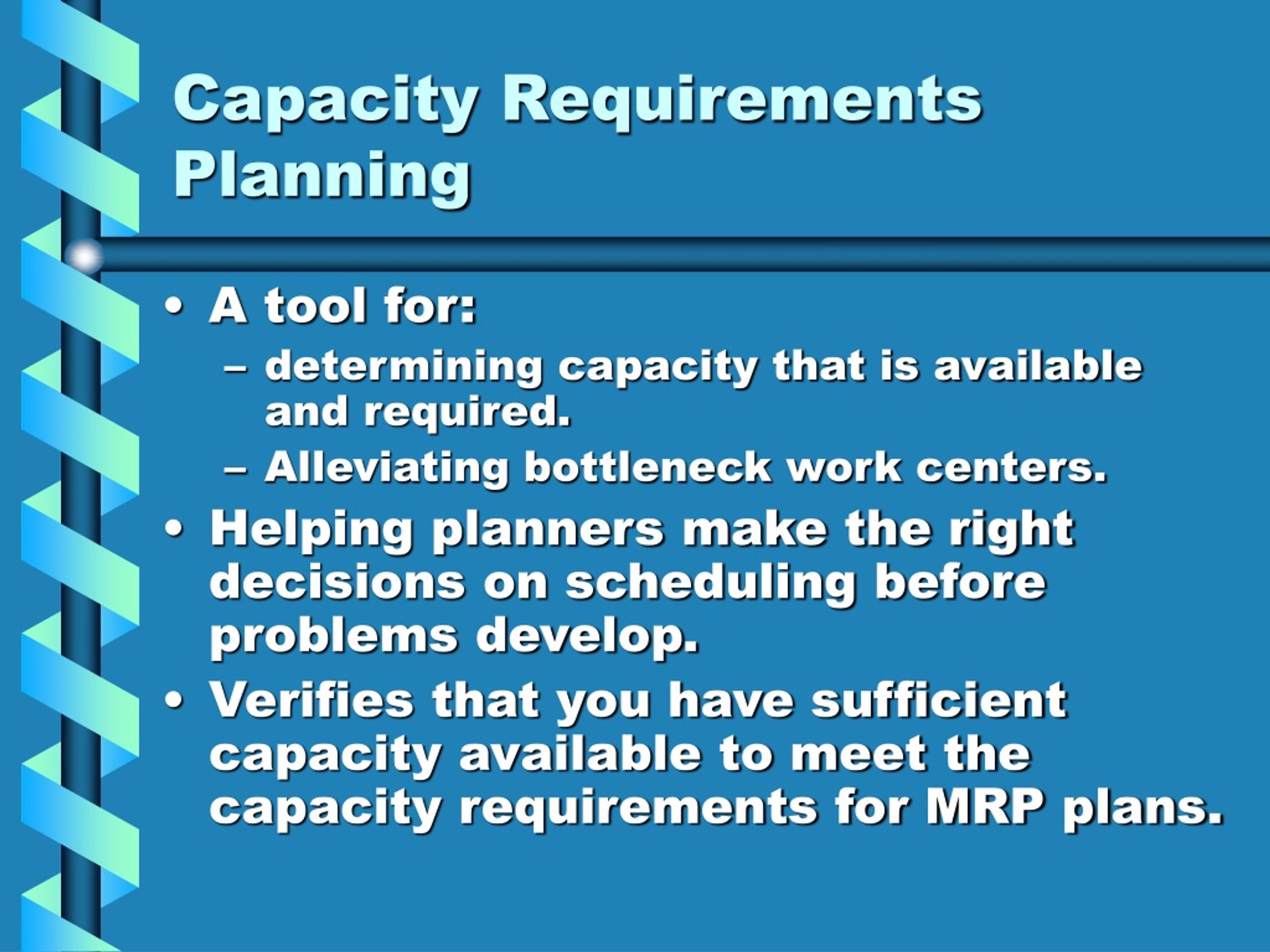

Capacity requirements planning (CRP) is a shortterm capacity planning technique that utilizes planned order releases from MRP in combination with information from routing sheets to estimate capacity needs, usually in standard hours, at individual machines or work centers. CRP is the last capacity planning step prior to detailed production.

Material requirements planning (MRP). Chapter 14 online presentation

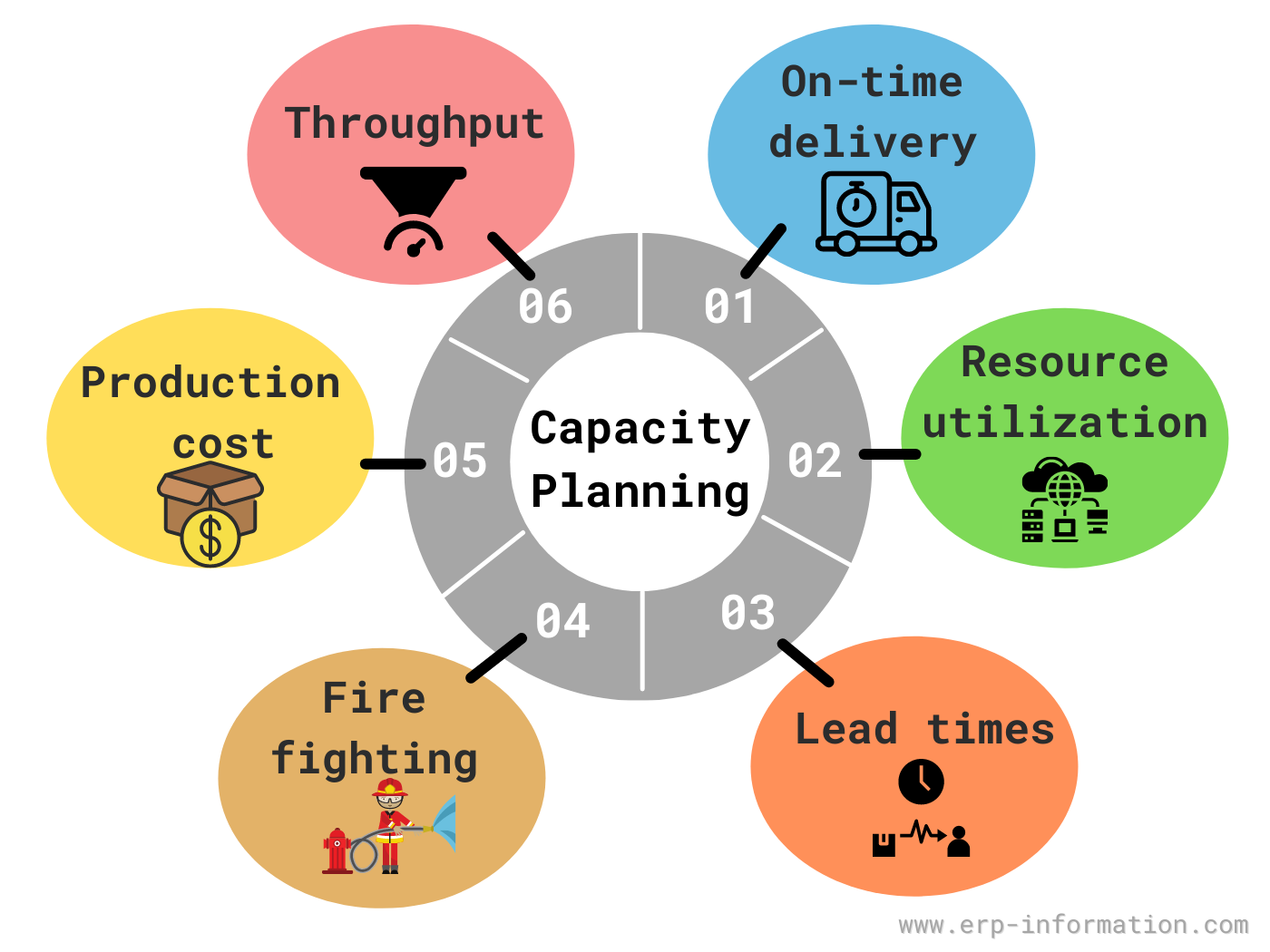

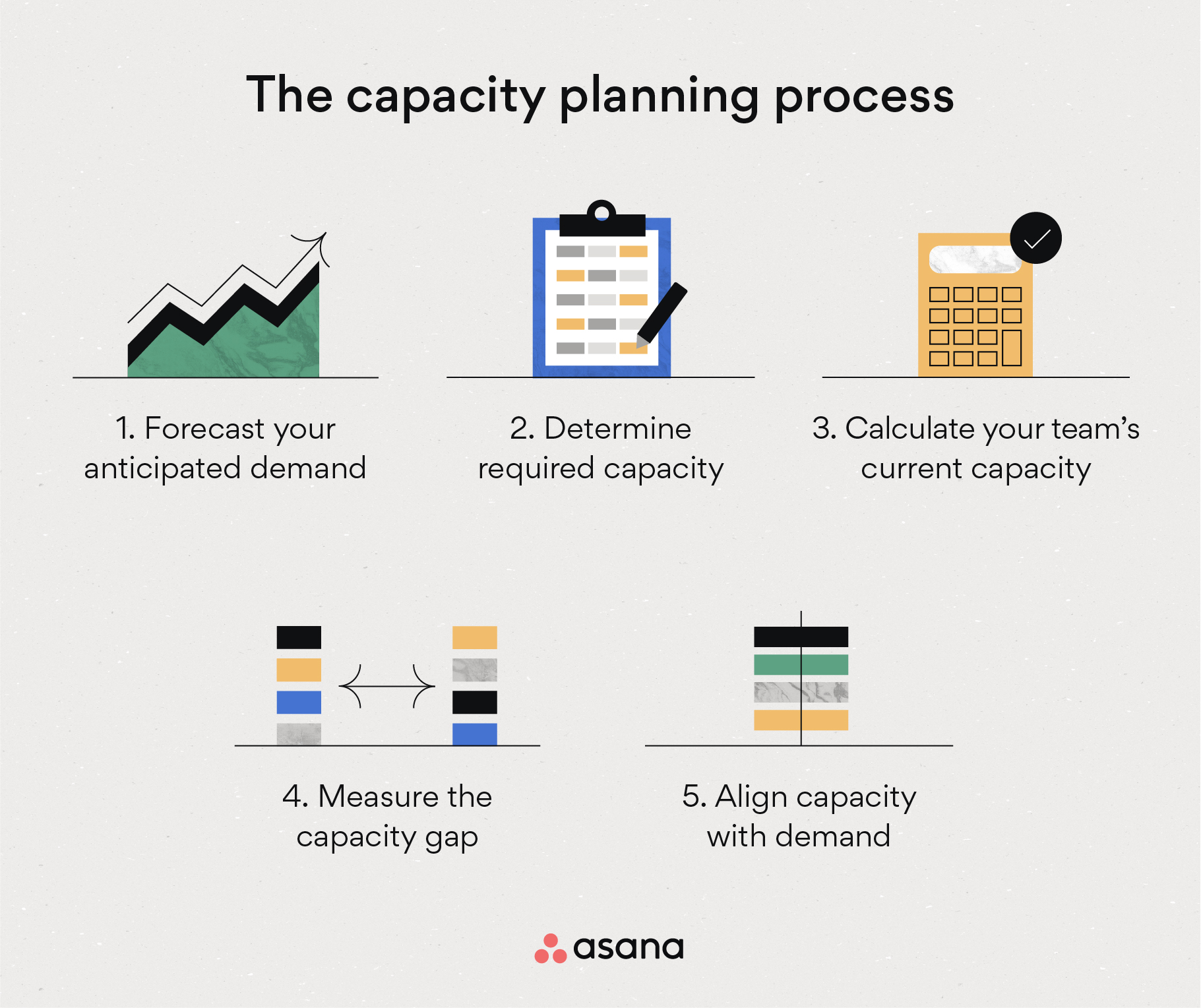

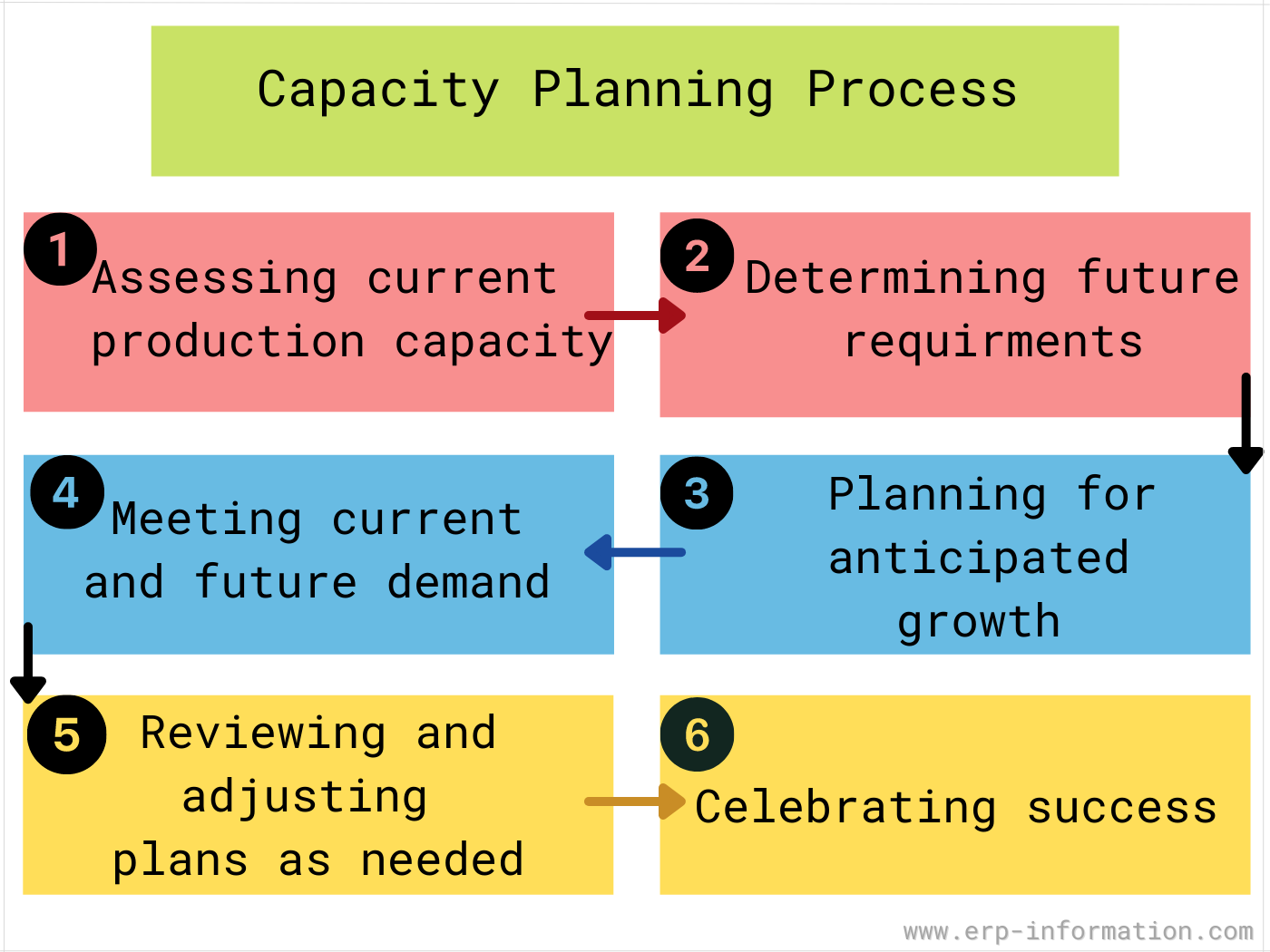

Capacity planning is a strategic process that aligns an organization's available resources with its projected demand. It involves a comprehensive analysis of an organization's workforce, tools, and production capabilities to ensure that the right resources are available at the right time to meet customer requirements.

Capacity Requirements Planning (CRP) Definition and Procedures

:max_bytes(150000):strip_icc()/CRP-FINAL-76cc22a55a2840468f7bd7741630ce9a.png)

Capacity Planning vs. Capacity Requirements Planning. The stage preceding capacity planning is capacity requirements planning. It is the process through which an organization determines how much it needs to produce and if it has the production capacity to do so.

Capacity Requirement Planning

Capacity Planning is part of the operational stage and works in conjunction with a manufacturing requirement planning (MRP) system. It's an essential step to make sure that resources are made available, and goods are routed through to the finished line. A detailed capacity requirement plan provides an operational level overview for production.

PPT Capacity Requirements Planning PowerPoint Presentation, free download ID915308

Capacity planning is a process that balances the available resources to meet customer demand or the project capacity requirements. Capacity, in project management and manufacturing terms, is the most work that can be done over a certain timeframe. In project management, the capacity planning process is very important because it's related to.

What is Capacity Planning? (Strategies, Process, and Best Practices)

Capacity Requirements Planning. Capacity requirements planning is the process of assessing future capacity needs and determining whether or not current capacity is sufficient to meet future demand. Capacity requirements can vary significantly from enterprise to enterprise. However, some common factors need to be considered in all cases.

PPT CAPACITY REQUIREMENT PLANNING (CRP) PowerPoint Presentation, free download ID6908910

Capacity requirements planning is the process of determining if the company's production capacity meets the production goals. It can also be referred to as CRP or capacity planning. This CRP system first analyses the company's planned manufacturing schedule. Later, this method examines if the production schedule has the capability to meet.

The Beginner's Guide to Capacity Planning for 2023 & Beyond Runn

.png)

The capacity requirements planning process, in operations management, is a comprehensive effort. It aims to evaluate and manage an organization's ability to meet both current and future demands. The key steps involved are as follows: Demand Forecasting: The foremost step is to identify the service level requirements.

Capacity Requirements Planning (CRP Plan and Strategies)

Capacity planning refers to balancing available resources to meet project capacity requirements or customer demand. Capacity in project and supply chain management is the amount of work an organization can complete in a specific time. The capacity planning process determines the production capacity needed to satisfy shifting consumer demand.

PPT CAPACITY REQUIREMENT PLANNING (CRP) PowerPoint Presentation, free download ID6908910

Capacity requirements planning (''CRP'') is the process of calculating the capacity available to a business for a given period, determining the unconstrained demand for that period, and.

Capacity Requirements Planning (CRP Plan and Strategies)

Capacity Requirements Planning Definition. Capacity requirements planning (CRP) is a process of establishing, measuring and adjusting the levels of capacity in an organisation within the context of Manufacturing Resource Planning (MRP 2) (CIPS: Glossary). It is a short-term capacity planning technique that entails evaluating the "ability of.

PPT Chapter 7. Capacity Planning and Management PowerPoint Presentation ID1643757

Capacity requirements planning (CRP) is the process of specifying the level of resources (facilities, equipment and labor force size) that best supports the enterprise's competitive strategy for production. Recommended Content for You. Research. IT Score for Sourcing & Procurement.

Capacity Requirement Planning Inventory Management Operations Management

Summary. Capacity planning is the process of determining the potential needs of your project. There are three types of capacity planning: lead capacity planning, lag strategy planning, and match strategy planning. Applying the right strategy will help your team feel prepared for changes in needed and available capacity.

PPT Capacity Requirement Planning PowerPoint Presentation, free download ID9141575

Capacity requirements planning is the process of determining if the company's production capacity meets the production goals. It can also be referred to as CRP or capacity planning.

What Is Capacity Planning and How To Apply The Right Strategy • Asana

Capacity planning. Capacity planning is the process of determining the production capacity needed by an organization to meet changing demands for its products. [1] In the context of capacity planning, design capacity is the maximum amount of work that an organization or individual is capable of completing in a given period.

A Comprehensive Guide On Capacity Planning (Strategies, Process Steps, Best Practices)

Capacity requirements planning is the process of determining whether a company's available production capacity can meet its production goals. Also known as CRP, capacity requirement planning first looks at the company's planned manufacturing schedule. This method then weighs the schedule against the company's production capabilities to.

.